We support high quality and high density processes to make competitive products.

・Machining:The most common metal processing technology. Using metal blades to cut metal plates, pieces, and bars. It is not suitable for ultra fine processing and hollow structures.

・Stamping:Cutting the metal with strong pressure created by using tooling on the stamping machine. It is good for big sized plates and high volume production but it easily gets curved or undercut on its surface.

・Laser cutting:Using melting technology to process. Since the machine quality improves, it also good for fine processing but it could have burr, dross, and heat damage on the surface.

・Diecasting:Put hot metal into a mold to get the pieces. It is good for metals with low melting points but tooling is expensive.

・Electro forming:Using plating and photo ething process to get fine patterns. It is limited by the deposition thickness and material.

・Photo Etching:Using the same exposure technology as semiconductor manufacturing, we expose patterns onto thin metal plates or pipes for etching. The initial fee is cheaper and it is suitable for high volume production.

■What is photo etching:

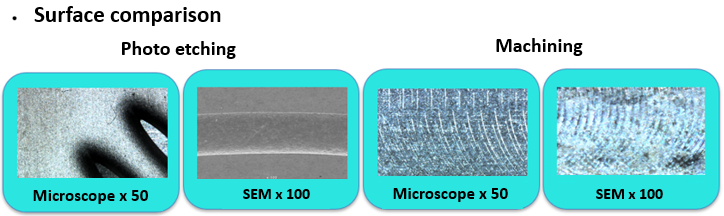

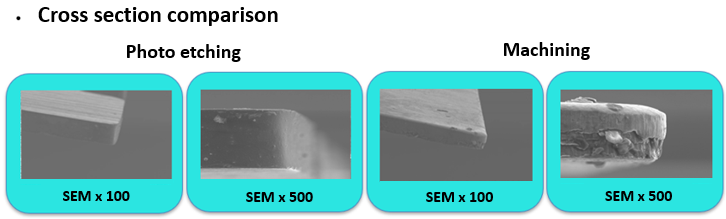

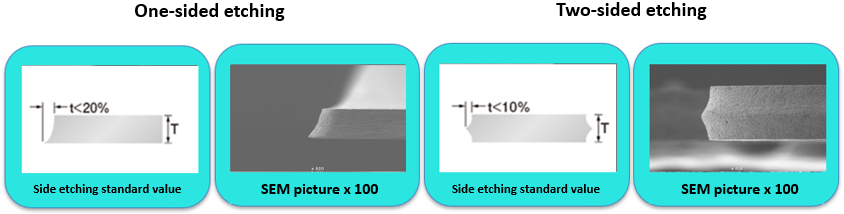

Photo Etching is known as a chemical corrosion process, an ideal technique for fabricating thin metal parts with very fine detail. Using a photo imaging technique, we are capable of precise and complex patterns on the micron level. Since it is a chemical process there is no burr, distortion or warpage after processing.

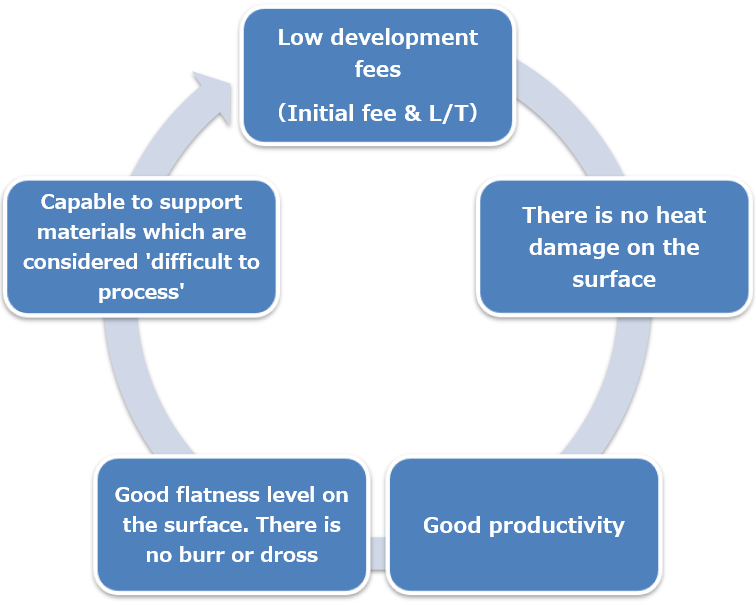

■Advantage

It is suitable for small, thin, fine and special shaped products like electronic components.

・Capable for complex and fine shapes on the micron level.

・No tooling necessary and can support small to large lots with minimal lead times.

・There is no burr or distortion after processing.

・Capable to work with any kind of metal.

・Suitable for high volume production.

Silver, Paladium, Copper, Brass, Phosphor Bronze, Berrillium Copper, Nickel Silver, Copper Titanium, Stainless Steel, Hastelloy, Inconel, Permalloy, Kovar, Tungsten, Molybdenum, Aluminum, Titanium, Magnesium, 42Alloy, Iron, Nickel, and more…